Released flexible substrates for high-temperature environments

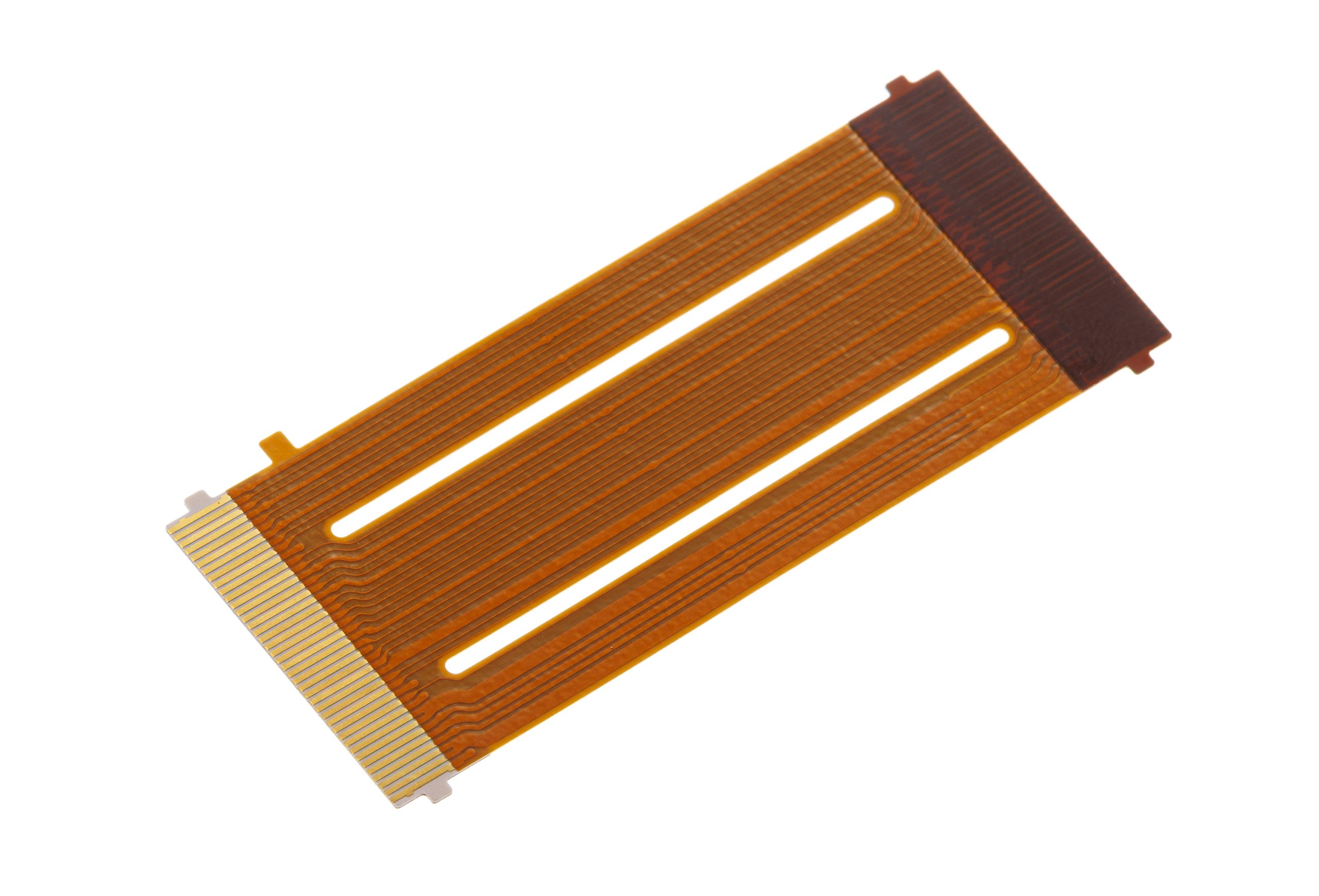

We have developed as a new product of the “YFLEX®”: one of the flexible printed circuit(FPC), a “High heat resistant FPC”.

Suitable for products used in high-temperature environments such as in-vehicle equipment, semiconductor manufacturing, and inspection equipment. We will start accepting orders globally from August 25.

High heat resistant FPC(YF series)

In recent years, there has been an increasing need to adopt FPCs in scenes that require high heat treatment, such as in-vehicle applications. In order to withstand even higher temperatures, it was necessary to improve the adhesion of the insulating layer that protects the circuit board and prevent the insulating layer from peeling off. The newly developed “High heat resistant FPC” achieves long-term reliability even in an environment of 150°C by increasing the heat resistance of the adhesive layer in the cover lay film that protects the surface of the FPC.

The features are as follows:

- Even after use in high temperature process at 150°C for 3,000 hours, there is no problem with electrical properties.

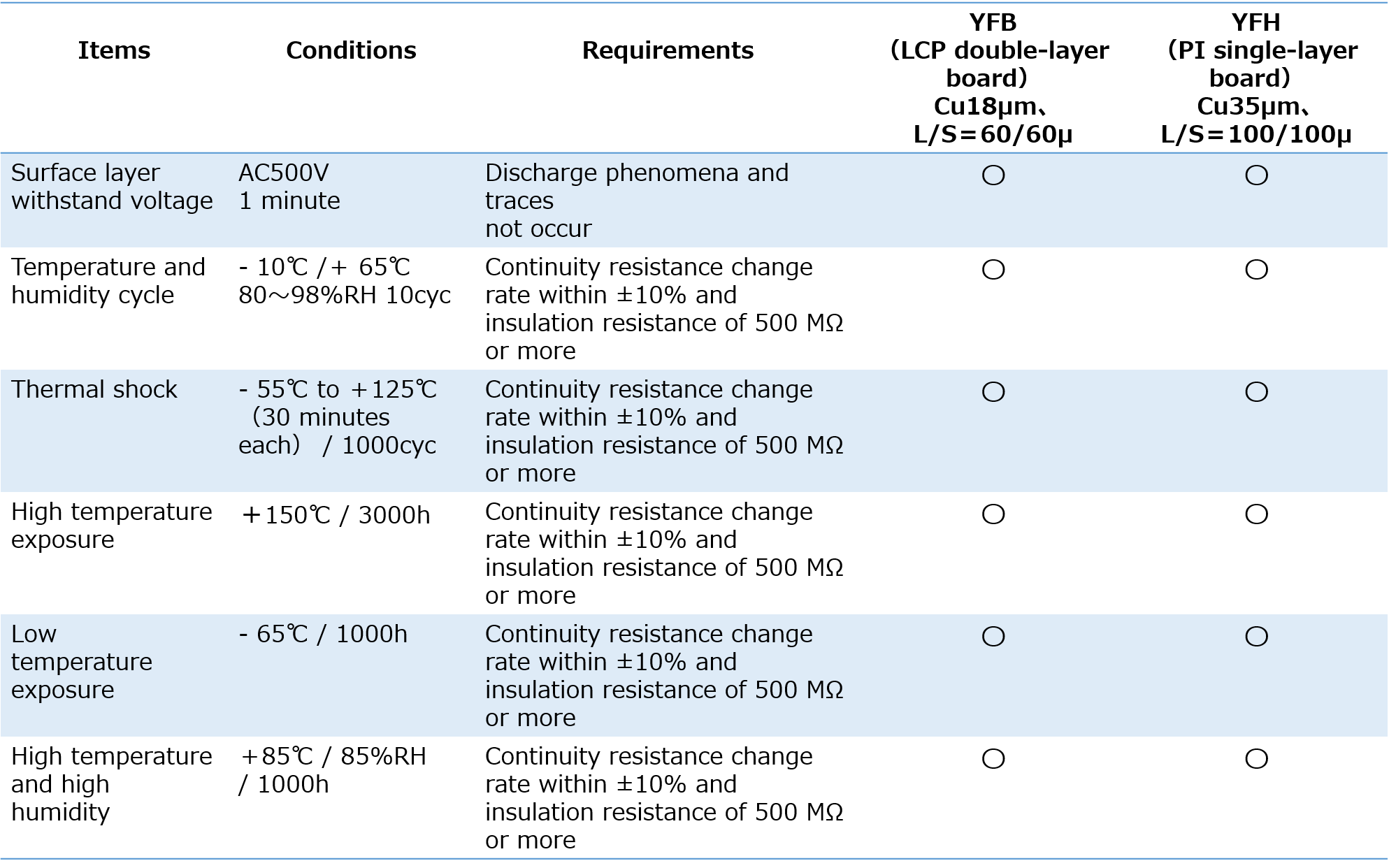

*Evaluation item: High temperature exposure at 150℃×3,000h

*Judgment criteria: Continuity resistance change rate within ±10% and insulation resistance of 500 MΩ or more

- Configurations can be single-layer or double-layer, and the insulation substrate base can be selected from liquid crystal polymer (LCP) or polyimide (PI).

Type: All 3 types

- YFA series (LCP base material, single-layer)

- YFB series (LCP base material, double-layer)

- YFH series (PI base material, single-layer / double-layer)

- Due to the reinforced GND design, it can be used not only for high heat resistant FPC applications but also for noise resistant FPC applications.

The reliability evaluation items are as follows: