Efforts to Reduce Environmental Impact

- TOP

- Sustainability

- Efforts to Reduce Environmental Impact

Measures to Reduce Energy Use

CO2 Emission Reduction Target

We would like to inform that Yamaichi Electronics group aims to reduce CO2 emission by 40% in 2030, compared to the basic unit per consolidated sales revenue of the fiscal year 2021. We will also try to meet carbon neutrality in 2050.

*Our CO2 emissions intensity is the CO2 emissions per consolidated sales revenue.

Actual result of CO2 emissions per unit in 2021: 0.36t/million yen

For more details, please visit: https://www.yamaichi.co.jp/en/sustainability/tcfd/

Metric tons per unit of sales

| FY2021 | FY2022 | FY2023 | FY2024 | Unit | |

|---|---|---|---|---|---|

| Metric tons per unit of sales (Scope1+2) |

0.36 | 0.29 | 0.34 | 0.32 | t-CO2/million yen |

Scope1

Consolidated past performance data

| FY2021 | FY2022 | FY2023 | FY2024 | Unit | |

|---|---|---|---|---|---|

| Gasoline | 62,549 | 72,718 | 76,750 | 78,388 | L |

| City gas | 852,603 | 533,093 | 108,319 | 84,610 | m3 |

| LP gas | 329 | 418 | 365 | 240 | m3 |

| Kerosene | 13,937 | 13,197 | 11,591 | 9,574 | L |

| Diesel fuel | 58,383 | 58,048 | 54,830 | 54,296 | L |

Consolidated CO2 emissions from energy sources

| FY2021 | FY2022 | FY2023 | FY2024 | Unit | |

|---|---|---|---|---|---|

| Scope1 CO2 | 1,624 | 1,161 | 506 | 546 | t-CO2 |

Scope2

Consolidated past performance data

| FY2021 | FY2022 | FY2023 | FY2024 | Unit | |

|---|---|---|---|---|---|

| Electricity | 23,510,267 | 22,802,568 | 22,076,459 | 25,168,800 | kWh |

Consolidated CO2 emissions from electricity consumption

| FY2021 | FY2022 | FY2023 | FY2024 | Unit | |

|---|---|---|---|---|---|

| Scope2 CO2 | 12,764 | 12,342 | 12,012 | 13,770 | t-CO2 |

Environmental Response

Efforts Toward Reducing CO2 Emissions

Introduction of solar power systems

The Sakura Factory (Sakura City, Chiba Prefecture) installed solar power generation equipment and NAS batteries in order to reduce the CO2 generated by purchasing power in October 2020. We have adopted a system that stores surplus solar power in the NAS battery during the day and discharges and uses it at night. As a result of the implementation of the system, the ratio of renewable energy to the amount of electricity used at the Sakura Factory is around 20%, reducing CO₂ emissions by approximately 350 tons annually.

-

Sakura Factory: 2,160 solar panels

-

Sakura Factory

NaS battery system

Capacity: 2,400 kWh

Output: 400 kW

At our German production base, Yamaichi Electronics Deutschland Manufacturing GmbH, 1,432 new solar panels with a capacity of 430 W each have been installed.

Introduction of electric vehicles

Previously, gasoline-powered vehicles were used to transport parts between Sakura Factory Buildings No.1 and No.2. As part of our efforts to promote environmentally friendly business activities, we introduced a new electric vehicle in November 2024.

Efforts Toward Environmental Protection

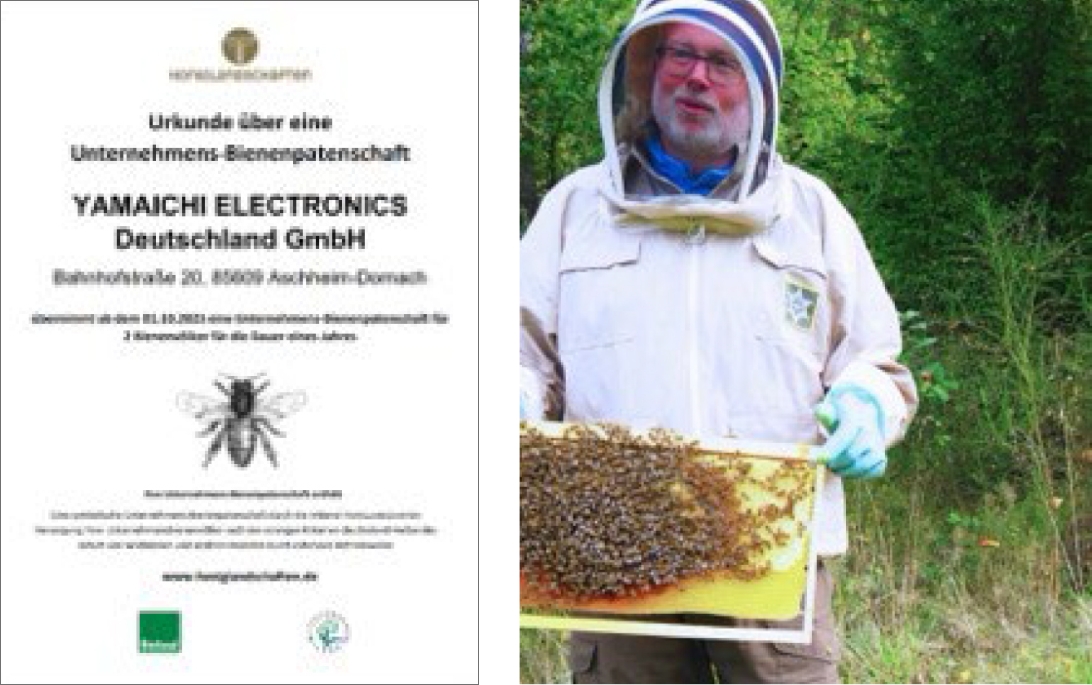

Support bee colonies

In Yamaichi Electronics Deutschland (YED), to protect bees that support the breeding of many plant species, we have partnered with the beekeeping company Honiglandschaften since October 1, 2022, to support two bee colonies.

Transformed ornamental lawn into a meadow

YED transformed approximately 5,000 m2 of extensive ornamental lawn at our production site in Frankfurt into a meadow consisting of various plants with different flowering periods. We expect this to create habitats for many insect species.

Forest regeneration

YED established a partnership with PLANT-MY-TREE®, which conducts forest regeneration projects in Germany, to support an area with 500 trees in Ratzdorf, Brandenburg.

Reduction and Promotion of Waste Recycling

The Yamaichi Electronics Group properly disposes of waste generated from business activities. Waste such as metal scrap, waste oil and liquids, grinding sludge, packaging materials, and waste plastics is appropriately classified. Additionally, some of the waste is sold as valuable materials, working towards effective resource utilization and reducing environmental impact.

Wastewater recycling

About 60% of wastewater from our plating facilities is recycled and reused through our in-house recycling equipment, except for a part disposed of as industrial waste. Recycled wastewater is reused in the plating manufacturing process.

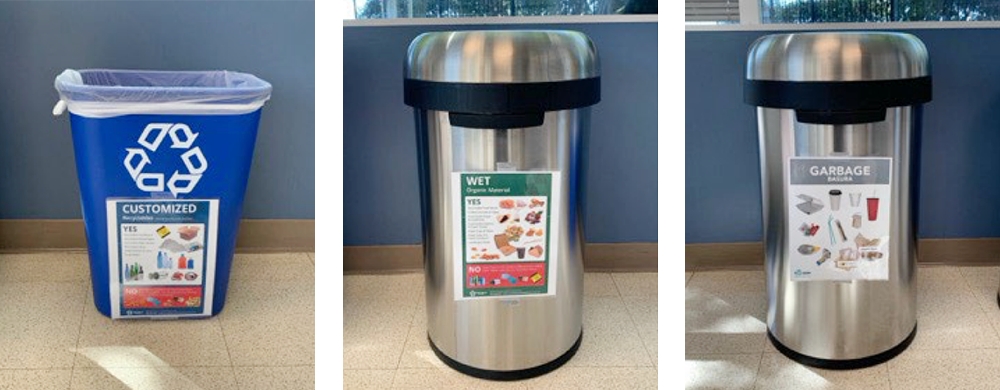

Waste sorting program

Yamaichi Electronics USA, Inc. (YEU) is partnering with Republic Services, a company that provides recycling programs and waste management and recycling services in San Jose to reduce waste and lower carbon dioxide emissions in the city and state. All employees at YEU participate in this program through daily waste sorting and recycling activities.

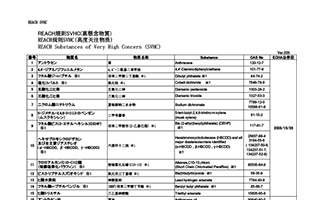

Green Procurement

Yamaichi Electronics Group complies with environmental laws,

procures materials and components with minimal environmental impact and provides environment-friendly products for our customers.