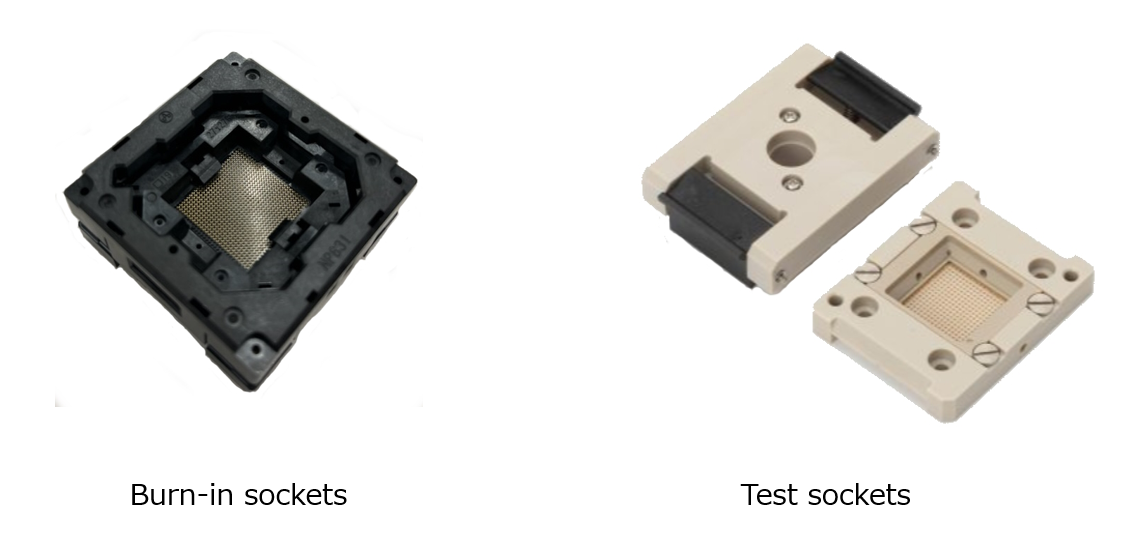

In my previous column, “What is a burn-in socket? An IC socket for inspection use that supports our comfortable lives,” We explained that there are two types of IC sockets for inspection: “burn-in sockets” and “test sockets”. IC sockets for inspection are used in the final inspection of semiconductor manufacturing processes, and Yamaichi Electronics enjoys a good reputation such as a “world-class market share.”

In this column, we will introduce the materials and technologies used to make IC sockets for inspection.

What Kind of Materials Are Used to Make IC Sockets for Inspection?

There are approximately 13,000 types of semiconductor packages, and burn-in and test socket shapes need to be flexible to suit the various formats.

Yamaichi Electronics’ test IC sockets must have characteristics that can withstand high temperature environments and high voltage stress. In addition, it is designed to be easy to use for various semiconductor inspection equipment and operators in the semiconductor back-end process, and to withstand strength.

In recent years, semiconductor packages such as BGA and QFP have become increasingly miniaturized, and Yamaichi Electronics’ inspection IC sockets are precisely made using advanced manufacturing technology.

What Materials Are Required for IC Sockets for Inspection?

- Heat resistant properties above 150°C

- High strength

- Good flow in molding dies and injection molding

- Good machinability

- Insulating and electrical resistance material

Super engineering plastics meet these requirements and are therefore used in our IC sockets for inspection. This material has excellent high temperature, voltage stress and machinability. Furthermore, by making full use of the injection molding and cutting technologies that Yamaichi Electronics has cultivated over many years, we can stably produce high-precision IC sockets for inspection in large quantities.

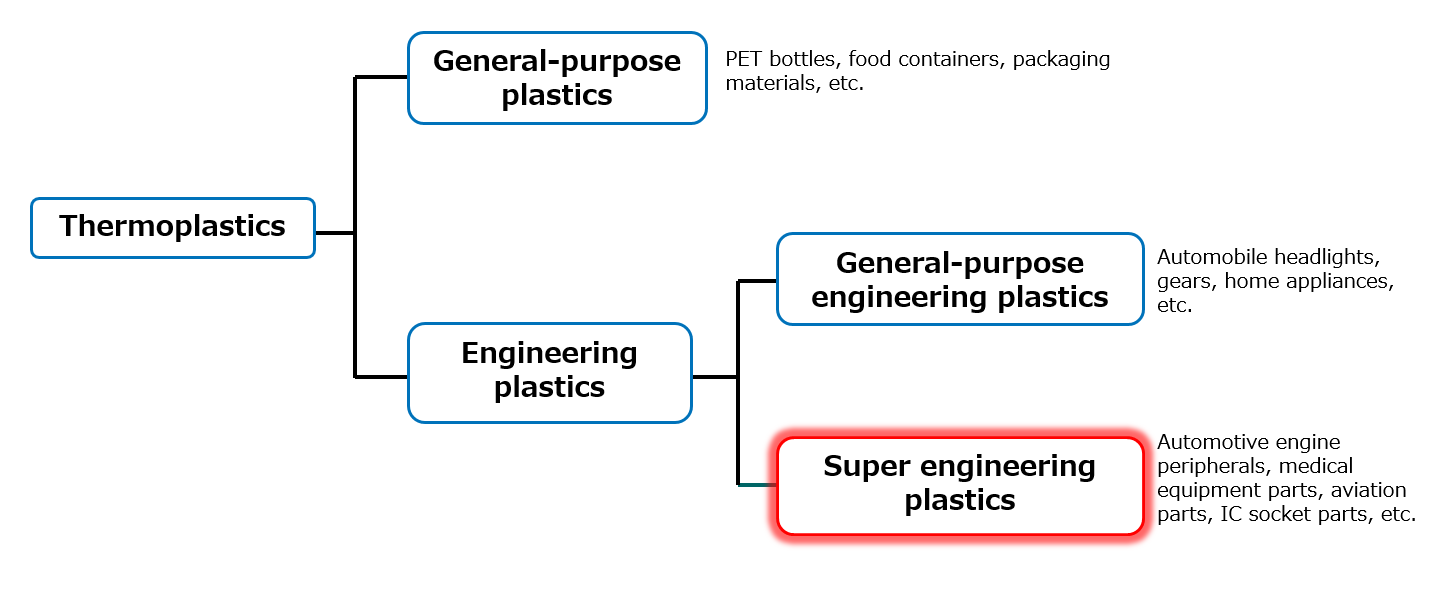

What Is Super Engineering Plastics Used for IC Sockets for Inspection?

PET bottles are made of polyethylene terephthalate, which is said to be the most widely used resin in the world. Although it is also used for all kinds of other applications, such as clothing and food trays, it is classified as a general-purpose plastic grade, and its heat resistance is limited to approximately 80°C to 100°C. It is not suitable as a material for IC sockets for testing, which require heat resistance properties. It is not suitable as a material for IC sockets for inspection, which require heat resistance characteristics.

On the other hand, the super engineering plastic used by Yamaichi Electronics has a heat resistance of over 150℃ and is 1.5 times stronger than general-purpose plastics. Generally used in automobiles, aircraft parts, and medical equipment parts, the flame resistance of this material has been evaluated for safety by the UL94 standard of the U.S. Underwriters Laboratories for Safety. Super engineering plastics are a suitable material for Yamaichi Electronics’ IC sockets for testing.

Positioning of Materials Used for IC Sockets for Inspection

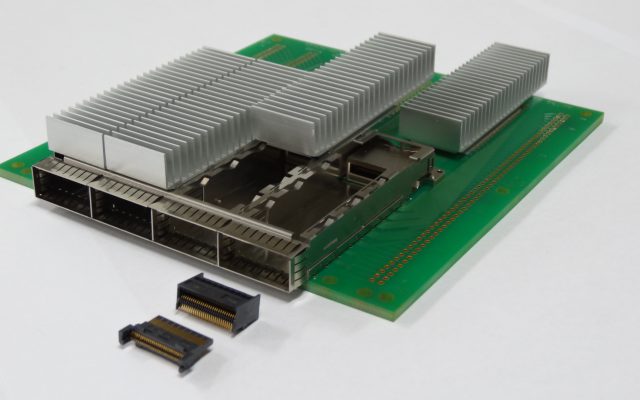

What Technology Is Used for the Parts?

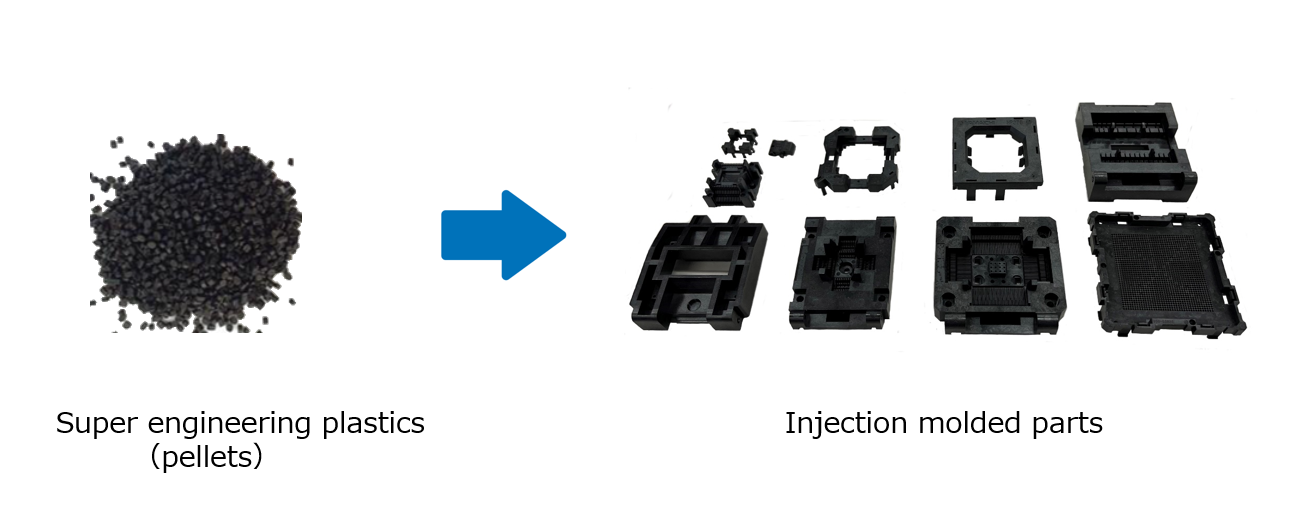

Parts of Burn-in Socket Are Made With Injection Molding Technology

In injection molding at Yamaichi Electronics, heat is applied to granular raw materials called pellets. Then, when it is in a molten state, it is injected into a mold. As it cools, it takes on the shape of a cavity created within the mold.

In order to flexibly respond to miniaturized semiconductor packages, we have the know-how to produce stable parts shapes using precision molding and molding technology.

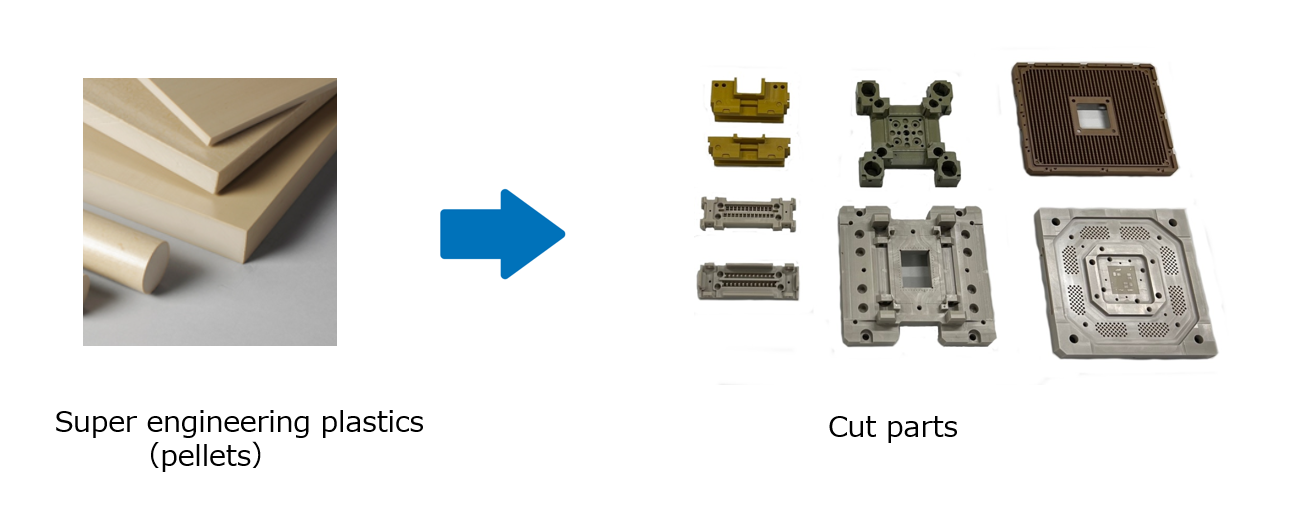

Parts of IC Sockets for Inspection Are Made With Cutting Technology

Yamaichi Electronics’ cutting technology uses cutting machines such as machining centers to process plates and bars of various materials. These cutting technologies are frequently used in Yamaichi Electronics’ test sockets and small-volume, high-mix products.

We have precise processing technology and know-how to produce stable parts shapes so that we can flexibly respond to miniaturized semiconductor packages.

Recent Trends in IC Sockets for Inspection and Semiconductors

Semiconductor packages are often installed in the computers, smartphones, home appliances, and automobiles that require high reliability. Furthermore, as semiconductor technology for data centers and generation AI continues to develop, semiconductor packages are expected to develop rapidly and support the DX.

Demand for Yamaichi Electronics’ IC sockets for inspection are increasing, and we will continue to support the improvement of semiconductor quality around the world with its advanced contact technology that “reliably connects” semiconductor testing equipment and semiconductor packages.

Please feel free to contact us if you have any questions about our semiconductor test solutions, from high-mix burn-in sockets in small volumes to custom-made burn-in sockets for special ICs.

If you are having trouble finding test solutions for semiconductor packages, from burn-in sockets for low-volume, high-mix production to custom-made inspection sockets for special semiconductor packages, please feel free to contact us.